T344CB Double Sided Teeth Jigsaw Blade

Introducing the T344CB Double Sided Teeth Jigsaw Blade

As a manufacturer based in China, we at [company name] are excited to introduce our latest and most innovative product yet – the T344CB double sided teeth jigsaw blade.

Designed to provide maximum utility for both professional woodworkers and DIY enthusiasts alike, this jigsaw blade is the result of years of research and development, coupled with a keen understanding of our customers’ needs and preferences.

In the following sections, we’ll dive deeper into what makes the T344CB double sided teeth jigsaw blade unique and how it can benefit your woodworking projects in numerous ways.

Double-Sided Teeth for Enhanced Cutting Power

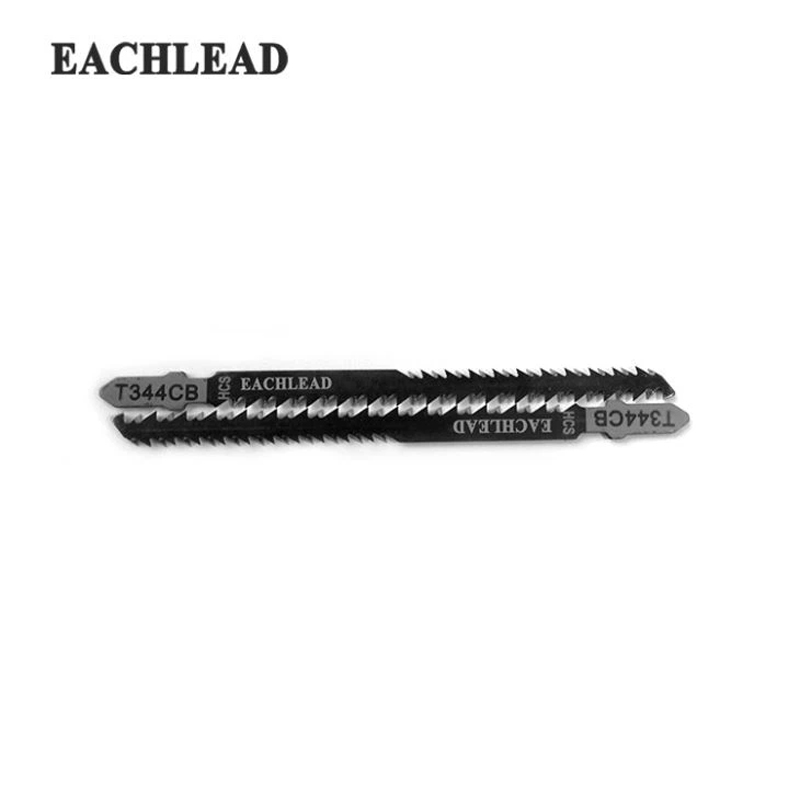

One of the key features of the T344CB double sided teeth jigsaw blade is its double-sided teeth design. Unlike conventional jigsaw blades that only have teeth on one side, our blade has teeth on both sides, which makes it perfect for cutting through thick materials like hardwood, metal, and composites.

Additionally, the double-sided teeth design also allows for smoother and more precise cuts, which is critical when working with intricate designs or patterns.

Hardened Teeth for Longer Blade Life

We all know how frustrating it can be to have to frequently change out jigsaw blades midway through a project. Fortunately, with the T344CB double sided teeth jigsaw blade, you won’t have to worry about that for a long time.

Our blade features hardened teeth that can last up to ten times longer than traditional jigsaw blades, which translates to fewer blade changes, less downtime, and more productivity.

Bi-Metal Construction for Versatility and Durability

Another unique aspect of the T344CB double sided teeth jigsaw blade is its bi-metal construction. Our blade is made up of two distinct metals – high-speed steel and high-carbon steel – which work in tandem to provide excellent cutting power, flexibility, and durability.

This design allows the blade to be used on a wide variety of materials, including wood, metal, plastics, and composites, without sacrificing performance or longevity.

Universal T-Shank Design for Maximum Compatibility

One of the most frustrating aspects of using jigsaw blades is having to constantly switch between different blade types to accommodate different jigsaw models and manufacturers. However, with the T344CB double sided teeth jigsaw blade, this won’t be an issue.

Our blade features a universal T-shank design that is compatible with the vast majority of jigsaw models and brands, allowing for ease of use and versatility across a wide range of applications.

Cuts in Both Directions for Clean and Efficient Results

Lastly, one of the standout features of the T344CB double sided teeth jigsaw blade is its ability to cut in both directions, which makes it ideal for difficult and complex cuts.

Not only does this feature lead to cleaner and more efficient results, but it also reduces the risk of chipping or splintering, which is particularly useful when working with delicate materials like veneers or laminates.

Conclusion

In summary, the T344CB double sided teeth jigsaw blade is a highly innovative and versatile product that offers a wide range of benefits for woodworking professionals and enthusiasts.

From its double-sided teeth and hardened construction, to its bi-metal design and universal T-shank compatibility, this blade is designed to enhance your cutting power, precision, and efficiency, while also reducing the need for frequent blade changes and downtime.

So if you’re looking for a high-quality jigsaw blade that can handle anything you throw at it, look no further than the T344CB double sided teeth jigsaw blade from [company name].

Most jigsaws require a blade to be screwed into the tool, but Bosch has since added the first tool less blade change system allowing a blade to be snapped into the tool.

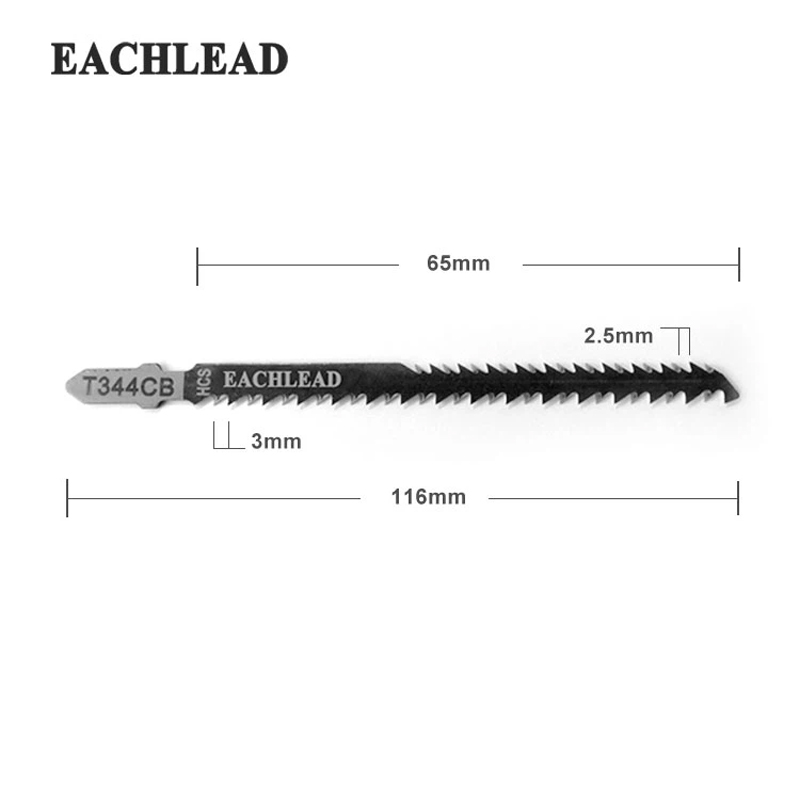

T344CB jigsaw blades double edged, variable tooth pitch jigsaw blades for very tight curves and socket cut outs.

115mm overall length 95mm working length, progressive tooth sizing allows thicker materials to be cut. These are very high quality blades.

The T344CB curved saw blade is a high-performance cutting tool that is specially designed to provide excellent cutting efficiency for high-carbon steel materials. This saw blade features a unique design that allows it to easily cut through tough materials, while also reducing the risk of blade bending or breaking.

The T344CB saw blade is constructed using high-quality materials and advanced manufacturing techniques, which ensures exceptional durability and longer blade life. It is also heat-treated to provide superior wear resistance, ensuring that it can withstand repeated use without losing its cutting edge.

Thanks to its high-end design, this saw blade offers exceptional cutting efficiency, saving time and effort when compared to other standard saw blades. Its teeth are sharp and durable, allowing it to slice through high-carbon steel materials with ease, while also reducing the amount of dust and debris produced during cutting.

Overall, the T344CB curved saw blade is a top-performing cutting tool that offers superior cutting efficiency for high-carbon steel materials. Whether you’re working on a tough construction project or a DIY project, this saw blade is sure to deliver excellent results.

Product description

| Model Number: | T344CB |

| Product Name: | Jigsaw Blade For Wood |

| Blade Material: | 1,HCS 65MN |

| 2,HCS SK5 | |

| Finishing: | Black |

| Print color can be customized | |

| Size: | Length*Working length*Teeth pitch : 116mm*90mm*Front Teeth 3.0mm/9Tpi

Back Teeth 2.5mm/10Tpi |

| Product Type: | T-Shank Type |

| Mfg.Process: | Ground Front Teeth / Ground Back Teeth |

| Free Sample: | Yes |

| Customized: | Yes |

| Unit Package: | 5Pcs Paper Card / Double Blister Package |

| Application: | Straight Cutting For Wood |

| Main Products: | Jigsaw Blade, Reciprocating Saw Blade, Hacksaw Blade, Planer Blade |

Blade Material

Different blade materials are used for different applications to improve blade life and cutting performance.

High-carbon steel (HCS) is used for softer materials such as wood, laminated particle board, and plastics due to its flexibility.

Production Process

FAQ

Q: Are you trading company or manufacturer?

A: We are professional power tool saw blades manufacturer since 2003.

Q: Can you provide samples?

A: Yes, we can provide samples for free, but you should be responsible for the freight cost.

Q: What package do you use for the products?

A: Usually we have professional retail package for the products. Customized package are also available based on certain MOQ.

Q: What is your MOQ?

A: MOQ is different for each item, you need to check with the sales person. But we need at least US$5000 for each LCL shipment.

Q: Where is your main markets?

A: Apart from the domestic market, Our product are mainly sold to Eastern Asia, North America, Western Europe, Eastern Europe, Southeast Asia, Mid East and Latin America, etc.