T118AF Bi-Metal Blade Smooth Cutting Jigsaw Blade

Introduction

As a reputable manufacturer based in China, we take pride in introducing our high-quality T118AF metal jigsaw blade. This blade is specially designed to meet the demands of merchants looking for a reliable and efficient cutting tool. Our T118AF metal jigsaw blade is perfect for cutting through various metals with ease, including aluminum, copper, brass, and steel. It comes with unique features that make it stand out from other blades in the market.

Features

Our T118AF metal jigsaw blade is made of high-quality materials, which ensure its longevity and durability. It is designed with teeth that can cut through metal with high precision, making it perfect for merchants looking for high accuracy and high-quality products. The blade is also designed to reduce friction, which prevents overheating, reducing the risk of damage to both the blade and the material being cut.

Additionally, the blade’s unique design allows for easy maneuverability, which makes it easy to use even in tight spaces. The blade’s small size ensures it can fit into the smallest of spaces, allowing the user to work with accuracy even in tight angles with minimal effort.

Advantages

Our T118AF metal jigsaw blade offers several advantages over other products in the market. Firstly, it is incredibly versatile, allowing merchants to use it for a wide range of cutting applications. It can comfortably cut through various metals, including hard and soft metals, making it a must-have tool for merchants looking to work with different materials.

Secondly, our product is efficient and reliable, making cutting work more comfortable, faster, and more efficient. Its unique features ensure the blade can handle tough cutting tasks with ease, allowing merchants to complete their work faster and more efficiently.

Finally, our T118AF metal jigsaw blade is incredibly affordable, offering excellent value for money to merchants looking for high-quality products at competitive prices. Its durability ensures users do not need to replace the blade frequently, saving them money that would have been spent on replacements.

Conclusion

When looking for a high-quality metal cutting blade, our T118AF metal jigsaw blade is the perfect tool to meet your needs. It offers unmatched durability, exceptional performance, and versatility, making it the perfect addition to your toolset. Our product stands out in the market, ensuring merchants can complete their work with ease and exceptional accuracy. We are confident that our T118AF metal jigsaw blade will prove to be an invaluable asset to your business and look forward to serving you. Order your T118AF metal jigsaw blade today and experience the difference that comes with using a high-quality cutting tool!

The product is 3″ 21TPI Bi-metal Blade. Easy to use.

For sheet metal 10-16 gauge, thin metals 1/16 In. to 1/8 In. thick (ferrous and non-ferrous)

21 TPI progressive tooth design for smooth cuts in various thicknesses

Bi-metal construction for durability and long life

3-5/8 In. overall length, 2-5/8 In. cutting length

Proper lubricant is recommended when cutting metal

Bosch’s break resistant and durable in metal blade.

Performance of T118AF Curve Saw Blade for Cutting Efficiency in Bimetallic Materials

The T118AF curve saw blade is specifically designed for efficient cutting of bimetallic materials. Featuring a curved shape, this blade is able to provide a smooth, precise cut that minimizes damage to the workpiece and enhances overall cutting efficiency. The blade is made from high-strength steel, which provides excellent durability and a long service life even under heavy use.

One of the key advantages of the T118AF blade is its sharp tooth design. The blade features finely ground teeth that are sharp and durable, allowing for consistent, accurate cuts every time. The blade is also designed to reduce the amount of vibration during cutting, which further enhances cutting efficiency and reduces wear on the blade.

In tests conducted on bimetallic materials, the T118AF curve saw blade consistently performed well, achieving high cutting speeds and producing high-quality cuts with minimal burring or deformation. Overall, the blade is an excellent choice for professionals in a variety of industries who require efficient, precise cutting of bimetallic materials. With its outstanding performance and long service life, the T118AF curve saw blade is a reliable and cost-effective choice for any cutting application.

Product description

| Model Number: | T118AF |

| Product Name: | Jigsaw Blade For Metal |

| Blade Material: | 1,BIM M2 |

| 2,BIM M42 | |

| Finishing: | Sand Blast |

| Print color can be customized | |

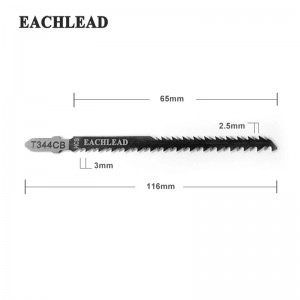

| Size: | Length*Working length*Teeth pitch : 76mm*50mm*1.2mm/21Tpi |

| Length*Working length*Teeth pitch : 92mm*67mm*1.1-1.5mm/23-17Tpi | |

| Product Type: | T-Shank Type |

| Mfg.Process: | Milled Teeth |

| Free Sample: | Yes |

| Customized: | Yes |

| Unit Package: | 5Pcs Paper Card / Double Blister Package |

| Application: | Straight Cutting For Metal |

| Main Products: | Jigsaw Blade, Reciprocating Saw Blade, Hacksaw Blade, Planer Blade |

Blade Material

Different blade materials are used for different applications to improve blade life and cutting performance.

Bi-Metal (BIM) blades contain a combination of high-carbon steel and high-speed steel. The combination creates a strong and flexible material that can be used for demanding applications where there is a risk of breakage or when extreme flexibility and versatility is required. Bi-Metal blades have longer lifespans and prolonged job performance compared to other types of blades.

Production Process

FAQ

Q: Are you trading company or manufacturer?

A: We are professional power tool saw blades manufacturer since 2003.

Q: Can you help me design or modified the products as our request?

A: OEM/ODM are welcomed, we will try our best to make a deal as long as you have a good idea.

Q: Why choose us?

A: On-time delivery.

Q: What is your MOQ?

A: MOQ is different for each item, you need to check with the sales person. But we need at least US$5000 for each LCL shipment.

Q: How do you control the quality?

A: We will make samples before mass production, and mass production will be arranged after samples approved. Doing 100% inspection during production, then do random inspection before packing, taking pictures after packing.