T118A Metal Cutting Jigsaw Blades

Introduction

Welcome to the world of T118A metal cutting jigsaw blades, the ultimate solution for all industrial cutting needs. These premium quality jigsaw blades are designed and manufactured by our expert team of engineers and technicians in state-of-the-art facilities in China to meet the highest quality standards. We are a renowned manufacturer and wholesale supplier of these high-performance jigsaw blades to merchants worldwide. As a leading manufacturer, we take pride in delivering premium quality tools that are designed to meet the highest industry standards, and our T118A metal cutting jigsaw blades are no exception.

Features and benefits

Our T118A metal cutting jigsaw blades are renowned for their exceptional quality, performance, and durability. The key features and benefits of our jigsaw blades are:

1. High-quality construction – Our jigsaw blades are made of premium quality high-speed steel, which is a type of tool steel that is known for its toughness, durability, and ability to hold an edge.

2. Precision cutting – Our T118A jigsaw blades are designed to cut through a range of metal materials with precision and accuracy, including sheet metal, thick tubing, angle iron, and more.

3. Smooth, clean cuts – Our jigsaw blades are engineered with precision-ground teeth that produce smooth, clean cuts with minimal burrs or rough edges.

4. Long-lasting – Our T118A jigsaw blades are designed to last longer than other blades on the market, thanks to their durable construction and cutting-edge design.

5. Wide compatibility – Our jigsaw blades are compatible with a range of popular jigsaw models, making them a versatile and essential tool for any professional or DIYer.

Applications

Our T118A metal cutting jigsaw blades are designed to cut through a range of metal materials, including:

1. Sheet metal – Our jigsaw blades are ideal for cutting through sheet metal of varying thicknesses, making them popular among builders, fabricators, and DIY enthusiasts alike.

2. Thick tubing – Our jigsaw blades are durable and long-lasting, making them an ideal choice for cutting through thick tubing, such as steel or aluminum.

3. Angle iron – Our jigsaw blades are engineered to cut through even the toughest materials, including angle iron or other thicker metal stock.

4. Other metals – Our jigsaw blades are versatile enough to cut through a range of other metal materials, making them ideal for a wide range of industrial, commercial, and residential applications.

Conclusion

In conclusion, if you are in the market for a high-quality jigsaw blade that delivers exceptional performance, reliability, and durability, our T118A metal cutting jigsaw blades are the perfect choice. As a leading manufacturer and wholesale supplier of these premium quality jigsaw blades, we take pride in delivering products that meet the highest quality standards and exceed expectations. Our T118A metal cutting jigsaw blades are the ultimate solution for all your industrial cutting needs, and we invite you to experience the quality and performance that our blades have to offer. Order now and start cutting like a pro!

This blade cuts metal less than 1/8-Inch thick.

For sheet metal 10-16 gauge, thin metals 1/16 In. to 1/8 In. thick (ferrous and non-ferrous)

17-24 TPI progressive tooth design for smooth cuts in various thicknesses

High-speed steel construction for maximum life in straight cuts

The T118A curve saw blade is a high-speed steel cutting tool with exceptional performance and efficiency. This blade is specifically designed to tackle a variety of cutting tasks with precision and accuracy, making it a popular choice for many industries.

The T118A blade is constructed using premium quality, high-speed steel materials that are engineered to withstand heavy-duty use and provide long-lasting durability. The blade’s unique design allows it to easily cut through a wide range of materials, including steel, non-ferrous metals, plastics, and other tough substrates.

One of the key benefits of the T118A curve saw blade is its exceptional cutting efficiency. The blade’s high-speed steel construction enables it to make quick, clean cuts with minimal drag, reducing the amount of time and energy required to complete a cutting task. Additionally, the blade’s curved shape allows for increased control and precision when cutting curved shapes or patterns.

Overall, the T118A curve saw blade is a reliable and efficient cutting tool that offers exceptional performance and durability when working with high-speed steel materials. Its unique design and construction make it an ideal choice for a wide range of cutting applications, and it is sure to deliver exceptional results every time.

Product description

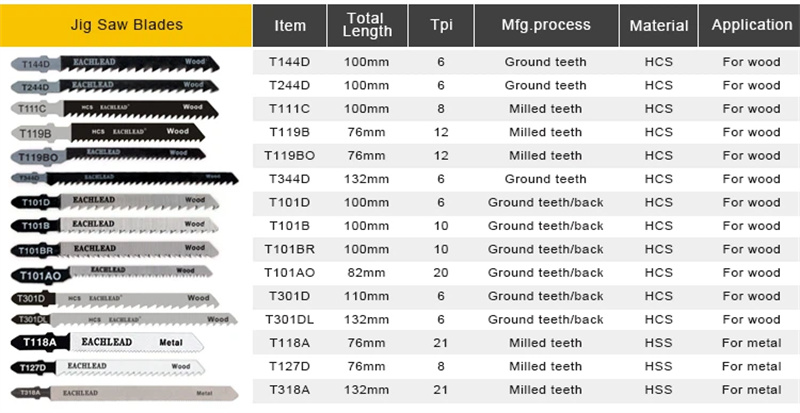

| Model Number: | T118A |

| Product Name: | Jigsaw Blade For Metal |

| Blade Material: | 1,HSS M2 |

| 2,HCS 65MN | |

| 3,HCS SK5 | |

| Finishing: | Sand Blast |

| Print color can be customized | |

| Size: | Length*Working length*Teeth pitch : 76mm*50mm*1.2mm/21Tpi |

| Length*Working length*Teeth pitch : 92mm*67mm*1.1-1.5mm/23-17Tpi | |

| Product Type: | T-Shank Type |

| Mfg.Process: | Milled Teeth |

| Free Sample: | Yes |

| Customized: | Yes |

| Unit Package: | 5Pcs Paper Card / Double Blister Package |

| Application: | Straight Cutting For Metal |

| Main Products: | Jigsaw Blade, Reciprocating Saw Blade, Hacksaw Blade, Planer Blade |

Blade Material

Different blade materials are used for different applications to improve blade life and cutting performance.

High-speed steel (HSS) is a stronger steel that can cut all types of metals.

High-carbon steel (HCS) is used for softer materials such as wood, laminated particle board, and plastics due to its flexibility.

Production Process

FAQ

Q: Are you trading company or manufacturer?

A: We are professional power tool saw blades manufacturer since 2003.

Q: Can you help me design or modified the products as our request?

A: OEM/ODM are welcomed, we will try our best to make a deal as long as you have a good idea.

Q: Our service

A: 24hours online technical support (telephone and email)

A: 100% Satisfaction Guarantee

A: Engineers are available

Q: What is your MOQ?

A: MOQ is different for each item, you need to check with the sales person. But we need at least US$5000 for each LCL shipment.

Q: How do you control the quality?

A: We will make samples before mass production, and mass production will be arranged after samples approved. Doing 100% inspection during production, then do random inspection before packing, taking pictures after packing.