T111C Saw Blade for Laminate Flooring

Introducing the T111C Saw Blade for Laminate Flooring: The Perfect Cutting Tool for All Your Flooring Needs

China is a global manufacturing powerhouse, and at the heart of this manufacturing ecosystem are quality products that serve various end-users around the world. Currently, China is producing high-quality saw blades that are designed to meet the needs of merchants looking for reliable, durable, and innovative cutting tools. One such saw blade is the T111C, specifically crafted for laminate flooring.

The T111C saw blade stands out because of its unique features, which make it an ideal product for merchants looking to meet the flooring needs of their customers. This blade is perfect for cutting and shaping laminate flooring, engineered flooring, and even hardwood. Here are some of the key features of this innovative saw blade:

1. Unique Design

The T111C saw blade is designed to handle high-speed cutting, which means that it can produce uniform slices, even on the toughest materials. The blade’s teeth are specially modified to maintain constant contact with the material being cut, resulting in smoother finishes and faster work. It has a TCG (triple chip grind) design that enables it to cut through dense materials with ease, making it ideal for hardwoods and laminates.

2. Durability

The T111C saw blade is built to last. Its construction is specifically designed to withstand the stresses of cutting through dense materials without losing its sharpness or longevity. The blade’s body is made of superior-grade steel, which helps to keep it sharp even after cutting through hundreds of pieces of laminate flooring. It is also coated with a hard-wearing, Teflon-like material that reduces friction, heat, and wear, making it last even longer.

3. Compatibility

The T111C saw blade can be used with all kinds of saws, including table saws, miter saws, and circular saws. Its universal hole pattern makes it easy to attach to any saw without the need for any adapters or extra fittings. This feature makes it possible to use the same saw blade across multiple cutting tools, making it an ideal choice for merchants who need to be able to adapt to different cutting scenarios quickly.

4. Ease of Use

The T111C saw blade is designed with the user in mind. It is easy to install and provides excellent cutting performance at all times. The blade’s unique design ensures that it keeps running smoothly, which makes the cutting process more manageable and less stressful. The blade’s design also reduces noise and vibration, enhancing the user’s experience even further.

5. Multipurpose cutting

The T111C saw blade can be used for a variety of cutting tasks beyond laminate flooring, including plastics, acrylics, PVCs, and even metal. This versatility makes it a practical and valuable investment for merchants looking for a high-quality saw blade that can handle a wide range of cutting tasks.

In conclusion, the T111C saw blade is an excellent choice for merchants who want to deliver high-quality flooring services to their customers. Its unique features, durability, compatibility, ease of use, and multipurpose cutting design make it a practical and valuable investment. Whether you are cutting laminate or other materials, the T111C saw blade is designed to deliver excellent results consistently.

Make the switch and invest in the T111C saw blade today. Your customers will appreciate the quality of work that comes with a well-designed and efficient saw blade. Remember, China’s manufacturing industry has a reputation for producing quality products – and the T111C saw blade is no exception!

If you’re interested in purchasing the T111C saw blade, please get in touch with us. Our company is committed to providing high-quality cutting tools to merchants worldwide, and we would be delighted to work with you.

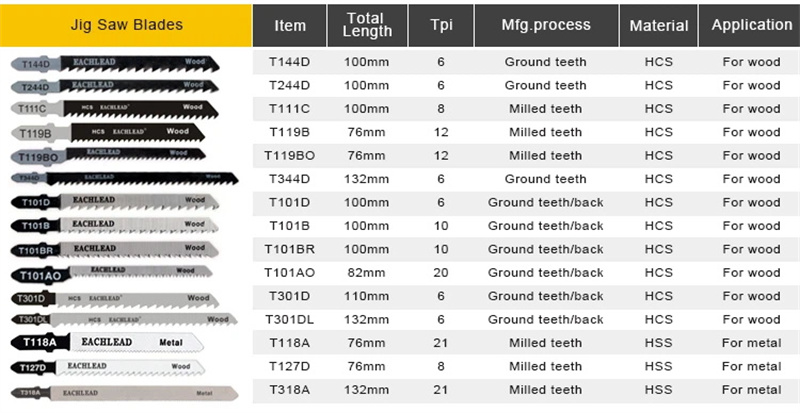

A Jigsaw works by attaching a blade accessory to the tool. Tooth design is important for the performance of a blade.

T111C 4-inch 8-tooth jig saw blade is designed for straight fine cuts in wood. The blade features a Bosch-style tang shank that eliminates the need for a set screw mounting hole, the most common breaking point on universal-mounting jigsaw blades.

The T111C model of curved saw blade showcases exceptional performance with its fast cutting efficiency on high carbon steel materials. This saw blade is ideal for precision cutting, and its curved design allows it to easily maneuver through curves and tight corners. With its high-quality construction, the T111C model ensures a clean and smooth cut every time, making it a popular choice among professionals and DIY enthusiasts alike. Whether you’re cutting through metal pipes, bars, or sheets, the T111C model guarantees excellent performance and precision.

Product description

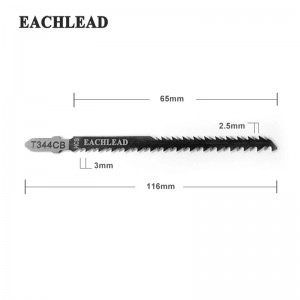

| Model Number: | T111C |

| Product Name: | Jigsaw Blade For Wood |

| Blade Material: | 1,HCS 65MN |

| 2,HCS SK5 | |

| Finishing: | Black |

| Print color can be customized | |

| Size: | Length*Working length*Teeth pitch : 100mm*75mm*3.0mm/8Tpi |

| Product Type: | T-Shank Type |

| Mfg.Process: | Milled Teeth |

| Free Sample: | Yes |

| Customized: | Yes |

| Unit Package: | 5Pcs Paper Card / Double Blister Package |

| Application: | Straight Cutting For Wood |

| Main Products: | Jigsaw Blade, Reciprocating Saw Blade, Hacksaw Blade, Planer Blade |

Blade Material

Different blade materials are used for different applications to improve blade life and cutting performance.

High-carbon steel (HCS) is used for softer materials such as wood, laminated particle board, and plastics due to its flexibility.

Production Process

FAQ

Q: Are you trading company or manufacturer?

A: We are professional power tool saw blades manufacturer since 2003.

Q: What payment terms do you have?

A: For small orders, we usually prefer Paypal and Western Union; for items that are not in stock, we charge 50% deposit and will ship goods out before the 50% balance are received.

Q: What can we provide ?

A: We are a professional manufacturer of saw and have our own packing centre. Through more than 10 years of effort, we have worked together with many good manufactuers of different tools as an exclusive tool club. We can provide our factory direct price for a vast range of products, including power tool accessories, hand tools, combination kits, etc.

Q: What is your MOQ?

A: MOQ is different for each item, you need to check with the sales person. But we need at least US$5000 for each LCL shipment.

Q: How about the delivery time?

A: Some items can be shipped in 15 days after receive the payment. Some customized item need 30~40 days after receive the advanced payment.