S922EF Reciprocating Saw Blades for Metal

Introduction

Reciprocating saw blades have become increasingly popular in recent years due to their versatility and effectiveness in cutting through various materials. They are commonly used in construction and demolition sites, woodworking, metalworking, and other DIY projects. As a manufacturer in China, we are proud to introduce our latest product, the S922EF reciprocating saw blades. Made with high-quality materials and advanced technology, our blades are designed to deliver efficient and precise cutting performance that exceeds the expectations of our customers. In this article, we will highlight some of the key features of our product and explain how they can benefit merchants looking to provide their customers with the best quality saw blades.

1. High-speed steel construction

One of the most important aspects of our S922EF reciprocating saw blades is their construction using high-speed steel. This material is renowned for its durability and resistance to wear and tear, even when cutting through tough materials like metal, aluminum, stainless steel, and iron. With these blades, merchants can be confident that they are offering their customers a product that is built to withstand the most demanding cutting tasks without losing its sharpness or effectiveness.

2. 8% cobalt content

Another key aspect of our reciprocating saw blades is their cobalt content. We use blades with an 8% cobalt content, which improves their strength, durability, and heat resistance. This means that they can work efficiently without overheating, leading to longer blade life, less downtime, and greater productivity. Merchants can be assured that by offering these blades, they are providing their customers with a tool that is built to last, even in the toughest cutting conditions.

3. Optimum tooth geometry

The S922EF reciprocating saw blades feature an optimum tooth geometry that offers fast and smooth cutting performance. The teeth are designed to achieve maximum efficiency by cutting smoothly through materials, reducing friction, and minimizing blade deflection. This translates into faster cutting speeds, less blade wear, and more accurate cuts. For merchants looking to provide their customers with blades that deliver superior performance, our S922EF model stands out with its exceptional tooth geometry.

4. Bi-metal construction

Our S922EF reciprocating saw blades are also built with bi-metal construction technology. This means that the blade consists of two separate materials – high-speed steel and high-carbon steel – which are joined together using a unique bonding process. The high-speed steel teeth ensure sharpness and durability, while the high-carbon steel body provides flexibility and resilience. This combination of materials results in a blade that is resistant to wear, capable of cutting through tough, dense materials, and can maintain its sharpness for a long time.

5. Universal fitting

Another important aspect of our reciprocating saw blades is their universal fitting. The blades are designed to fit most types of reciprocating saws available on the market. This makes them an attractive choice for merchants who want to offer a product that is versatile and can meet the needs of a wide range of customers. With our universal fitting design, merchants can be confident that our blades will fit easily into their customer’s saws, without the need for any additional adapters or modifications.

Conclusion

The S922EF reciprocating saw blades are a testament to our commitment to providing high-quality, durable products to our customers. With their high-speed steel construction, 8% cobalt content, optimum tooth geometry, bi-metal construction, and universal fitting, our blades deliver superior performance, durability, and accuracy. Merchants looking to provide their customers with the best quality reciprocating saw blades can rely on our S922EF model to meet their needs. With our blades, their customers can be confident in their ability to tackle even the toughest cutting tasks with ease and precision.

The S922EF saw blade is a high-performance cutting tool specially designed for cutting bi-metal materials. With its advanced dual-metal construction, this saw blade is capable of delivering outstanding cutting efficiency and precision in a wide range of applications.

The S922EF saw blade features a combination of high-speed steel (HSS) teeth and cobalt-optimized Bi-Metal construction, which provides excellent wear resistance and long service life, even when cutting through tough metals. This combination of materials allows the blade to cut through a wide variety of bi-metal materials with ease, including steel, aluminum, copper, and other metals commonly used in industrial applications.

In terms of performance, the S922EF saw blade has been shown to produce a high cutting rate and excellent surface finish, with minimal burring and deformation. This makes it an ideal choice for high-speed cutting operations, such as metal fabrication, automotive manufacturing, and construction applications.

Overall, the S922EF saw blade is a reliable and efficient cutting tool that offers exceptional cutting performance and long service life. So, it is a perfect choice for any application where precision cutting of bi-metal materials is required.

Product description

| Model Number: | S922EF |

| Product Name: | Reciprocating Saw Blade For Metal |

| Blade Material: | 1,BI-METAL 6150+M2 |

| 2,BI-METAL 6150+M42 | |

| 3,BI-METAL D6A+M2 | |

| 4,BI-METAL D6A+M42 | |

| Finishing: | Print color can be customized |

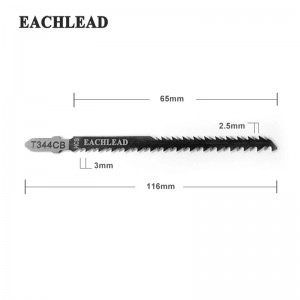

| Size: | Length*Width*Thickness*Teeth pitch : 6inch/150mm*19mm*0.95mm*1.4mm/18Tpi |

| Application: | thin sheet metal:1.5-4mm |

| pipes/profiles:dia.5-100mm | |

| Mfg.Process: | Milled Teeth |

| Free Sample: | Yes |

| Customized: | Yes |

| Unit Package: | 2Pcs Blister Card / 5Pcs Double Blister Package |

| Main Products: | Jigsaw Blade, Reciprocating Saw Blade, Hacksaw Blade, Planer Blade |

Blade Material

Different blade materials are used for different applications to improve blade life and cutting performance.

Bi-Metal (BIM) blades contain a combination of high-carbon steel and high-speed steel. The combination creates a strong and flexible material that can be used for demanding applications where there is a risk of breakage or when extreme flexibility and versatility is required. Bi-Metal blades have longer lifespans and prolonged job performance compared to other types of blades.

Production Process

FAQ

Q: Are you trading company or manufacturer?

A: We are professional power tool saw blades manufacturer since 2003.

Q: Our service

A: 24hours online technical support (telephone and email)

A: 100% Satisfaction Guarantee.

Q: What should we do if there is some problems with the products we bought from you?

A: Please contact us and point out what is the problem, our after-sale service will focus our attention immediately.

Q: Shipping way

A: Small quantity: by international air express, within 3-7days arriving.

A: Large quantity: by ocean cargo, arriving time depends on customers destination.

Q: How do you control the quality?

A: We will make samples before mass production, and mass production will be arranged after samples approved. Doing 100% inspection during production, then do random inspection before packing, taking pictures after packing.